To properly document maintenance for warranty purposes, you should record detailed, accurate information like equipment ID, work performed, parts used, personnel involved, and dates. Use standardized formats and digital tools to guarantee consistency and prevent errors. Store records securely with access controls, regularly update them, and back up data for reliability. Good documentation supports warranty validation and future troubleshooting, so ensuring thorough, organized records is essential—keep going to discover how to improve your record-keeping process even further.

Key Takeaways

- Use standardized templates and digital tools to record maintenance activities accurately and consistently.

- Document equipment details, work performed, parts used, personnel involved, and dates for traceability.

- Include inspection results, calibration data, and any modifications to ensure comprehensive records.

- Store records securely with controlled access, regular backups, and organized indexing for easy retrieval.

- Maintain records promptly and review them regularly to ensure accuracy, completeness, and compliance for warranty validation.

The Significance of Precise Service Documentation

Precise service documentation is essential because it provides a clear record of maintenance activities, enabling you to track equipment performance over time. With accurate records, you can identify recurring failures and refine preventive strategies, boosting reliability. Detailed documentation helps you optimize maintenance schedules by aligning interventions with actual equipment conditions and past trends, avoiding unnecessary downtime. It also allows you to prioritize critical tasks, reducing emergency repairs and unplanned outages. Properly recorded service activities support compliance with industry standards and safety regulations, safeguarding your operations legally and operationally. Additionally, continuously analyzing documented actions fuels ongoing improvements, helping you enhance asset performance incrementally. Reliable documentation is the foundation for informed decision-making, ensuring your maintenance processes are effective and aligned with your operational goals. Proper data collection and analysis further enhance your ability to forecast future maintenance needs and support strategic planning, especially when considering regulatory compliance, that may influence maintenance practices. Incorporating comprehensive record-keeping into your maintenance approach can facilitate better audits and reviews, ensuring continuous adherence to standards. Furthermore, maintaining detailed maintenance history can help identify trends that lead to improved system longevity and performance.

Essential Details to Record During Maintenance

When recording maintenance, you need to include equipment identification details to guarantee traceability. You should also clearly document the work performed, including inspections, repairs, or replacements, along with the personnel and timing information. Accurate records help verify compliance and support warranty claims, so be precise and thorough in capturing these essential details. Additionally, maintaining comprehensive documentation of the aircraft’s airworthiness status, such as ADs, SBs, and modifications, ensures that all maintenance activities are properly supported and verifiable. Incorporating predictive modeling insights can further optimize maintenance schedules by forecasting potential issues before they arise. Proper documentation of eye patch benefits and related skincare routines can also be crucial for medical or cosmetic tracking, especially in professional or clinical settings. Regularly updating maintenance logs with color accuracy details can help in troubleshooting and calibration processes, ensuring high-quality performance over time.

Equipment Identification Details

Recording accurate equipment identification details during maintenance is essential for guaranteeing proper tracking, accountability, and efficient service. Start by documenting the equipment’s name or tag, such as “Delivery Truck #123,” to clearly distinguish it. Include the serial number assigned by the manufacturer to track the specific unit. Record the model number for precise identification of type and specifications, along with manufacturer details like the company name and contact info for warranty and service purposes. Note the physical location where the equipment is housed to facilitate planning and accountability. Additional details like the purchase date, first use, and responsible operator help monitor lifecycle and operational history. These identification elements ensure maintenance records are thorough, accurate, and useful for future reference or audits. Proper documentation practices are crucial for maintaining comprehensive service records and streamlining warranty claims. Implementing a standardized recording process can further improve data consistency and retrieval efficiency.

Work Performed Description

A clear and detailed description of the maintenance tasks performed is essential for ensuring that everyone involved understands exactly what was done. You should document the procedures used, referencing relevant manuals or bulletins, and specify any inspections, replacements, or installations. Recording all actions, including parts used and components replaced, ensures traceability. Use work orders to capture completion dates, follow-up tasks, and technician notes, then transfer this information to your maintenance system for accuracy. Supporting documents like manuals or certifications should be attached or referenced to verify compliance. Additionally, conducting comprehensive risk assessments can help identify potential vulnerabilities during maintenance procedures, thereby supporting security vulnerabilities mitigation efforts. Incorporating standardized documentation practices helps streamline record-keeping and facilitates future maintenance planning.

Personnel and Timing Data

Accurate personnel and timing data are essential for maintaining clear maintenance records and ensuring accountability. You should record the full legal name and unique identification number of each technician involved for precise tracking. Document the date of hire or employment start to establish maintenance timelines and warranty periods. Include the job title or role to clarify responsibilities and certifications. Keep copies of official IDs for verification. Record the exact date and time of each maintenance activity to ensure proper chronological order and warranty compliance. Note shift assignments and task durations for accountability and efficiency analysis. Additionally, document who accessed records, along with access times, to maintain security. Implementing comprehensive record-keeping practices helps in tracking maintenance history and resolving disputes effectively. Maintaining these records in a secure, compliant manner is crucial to protect sensitive information and adhere to privacy laws. It is also beneficial to regularly review and update these records to ensure ongoing accuracy and compliance with evolving privacy regulations. Verifying that access controls are properly managed is vital for safeguarding sensitive information and preventing unauthorized disclosures. Always verify these details are securely stored and compliant with legal retention and privacy requirements.

Standardized Formats for Consistent Record-Keeping

Standardized formats for maintenance logs are essential to guarantee consistency and clarity across your maintenance teams. Using predefined fields and templates ensures all critical information is captured uniformly, reducing misunderstandings. Consistent terminology, units of measurement, and organized grouping by equipment or task make it easier to compare records and analyze trends. Including key elements like equipment details, maintenance activities, personnel involved, parts used, and safety checklists improves accuracy and regulatory compliance. Digital formats, such as spreadsheets or CMMS systems, facilitate real-time data entry, automation, and easy access. Regularly reviewing and updating templates keeps them aligned with evolving requirements. Proper documentation also helps in identifying signs of issues early, such as spoiled lemon juice, preventing costly repairs or safety hazards. Utilizing standardized formats can streamline audits and inspections, ensuring all necessary information is readily available. Training your team on standardized formats ensures everyone contributes accurate, complete records, supporting efficient maintenance, better warranty claims, and regulatory adherence.

Organizing and Storing Service Records Effectively

To keep your service records organized and accessible, you should implement centralized storage solutions that are both secure and easy to manage. Arranging your records chronologically helps you locate documents quickly and guarantees proper retention. Additionally, establishing secure access protocols protects sensitive information while allowing authorized team members to retrieve records efficiently. Regular audits and monitoring can identify potential vulnerabilities in your storage system and ensure continued compliance with data privacy laws. Incorporating effective record-keeping practices and the use of secure digital platforms can also enhance clarity and engagement, making it easier for team members to understand and follow procedures. Maintaining comprehensive documentation is essential for tracking service history and supporting warranty claims effectively.

Centralized Storage Solutions

Have you ever wondered how organizations keep their service records organized, secure, and easily accessible? Centralized storage solutions make this possible by combining physical security measures with advanced digital management. Offsite facilities use multi-layered security, fire suppression, and climate control to protect records from theft, fire, and deterioration. Secure vaults or underground storage add extra protection for sensitive files. Digital inventory management software with barcoding and real-time tracking helps you locate records quickly. Online portals enable you to manage, search, and request documents effortlessly. Ensuring document integrity is crucial for maintaining trust and accuracy in record-keeping, and implementing proper security protocols further enhances data protection. Certifications and industry standards ensure that records are compliant with legal and regulatory requirements. These solutions also optimize space, reduce costs, and provide flexible storage options that scale with your needs, making record management efficient and dependable. Professional records storage provides long-term protection and preservation of business records, ensuring security, accessibility, and regulatory compliance.

Chronological Record Organization

Organizing service records chronologically provides a clear and accurate view of an asset’s maintenance history, making it easier to track events over time. You’ll see the order of repairs, inspections, and replacements at a glance, helping identify patterns or recurring issues. To do this effectively, you should:

- Gather all relevant documents like invoices, reports, and warranty claims

- Sort records strictly by service date, from earliest to latest

- Use a consistent date format (e.g., YYYY-MM-DD) for clarity

- Segment records by type or provider within the timeline

- Index major milestones or incidents for quick navigation

- Utilize digital tools or software to automate and enhance the organization process, ensuring accuracy and ease of access. Incorporating maintenance history data can provide deeper insights into the asset’s performance and longevity.

This organized timeline supports warranty claims, simplifies audits, and helps you understand maintenance cycles. Keeping records in order ensures you always have an accurate and thorough asset history.

Secure Access Protocols

Are you guaranteeing that your service records are protected against unauthorized access? Implement strict access controls by limiting record access to authorized personnel only. Use multi-factor authentication and strong, unique passwords to strengthen login security. Apply Role-Based Access Control (RBAC) to assign permissions based on job roles, and regularly review these privileges to reflect personnel or organizational changes. Monitor and audit access logs consistently to detect any unauthorized activity and maintain accountability. Encrypt data both at rest and during transmission to prevent interception. Use secure digital storage solutions, such as certified electronic archiving systems and encrypted cloud platforms, to safeguard records. Additionally, train employees on security best practices and conduct routine audits to ensure compliance, protecting your service records from internal and external threats. Implementing layered security measures can further enhance protection by addressing potential vulnerabilities comprehensively.

Ensuring Accessibility and Security of Documentation

Making certain that the accessibility and security of documentation is essential for maintaining efficient and confidential medical records. You need a centralized, organized system, whether physical or electronic, to enable quick retrieval by authorized personnel. Using EMR or EHR systems helps track maintenance history seamlessly. Consistent use of standard abbreviations improves clarity across users. Regular staff training reinforces confidentiality and security protocols. To safeguard records, store physical files in locked locations, and restrict electronic access with passwords and encryption. Conduct periodic audits to verify compliance. Additionally, maintain proper indexing and retention policies, adhering to regulations like CMS, to make sure records are available for audits or legal needs. Implementing security measures such as access controls and audit trails is vital for protecting sensitive information. Balancing prompt access with confidentiality safeguards keeps your documentation reliable and secure.

The Importance of Timely and Accurate Data Entry

Maintaining secure and accessible documentation relies heavily on the quality of data entry practices. When you enter data promptly and accurately, you enable proactive maintenance scheduling, reducing downtime and preventing equipment failure. Real-time updates help with troubleshooting and improve responsiveness, allowing your team to adjust plans based on current conditions. Conversely, delays can cause missed deadlines, increased repair costs, and shortened asset lifespan. Accurate records also support better decision-making, cost control, and regulatory compliance. Use standardized formats and digital tools with validation features to minimize errors. Regular audits and training reinforce good habits. Consider this table to understand the impact:

| Timeliness | Accuracy | Cost Control |

|---|---|---|

| Prevents downtime | Ensures reliable decisions | Tracks labor/material costs |

| Supports forecasting | Facilitates trend analysis | Identifies recurring issues |

| Enables quick troubleshooting | Avoids costly mistakes | Reduces warranty risks |

| Improves responsiveness | Ensures compliance | Aids budget planning |

| Minimizes asset failure | Strengthens legal safeguards | Enhances cost forecasting |

Additionally, maintaining up-to-date maintenance records is crucial for accurate analysis and planning.

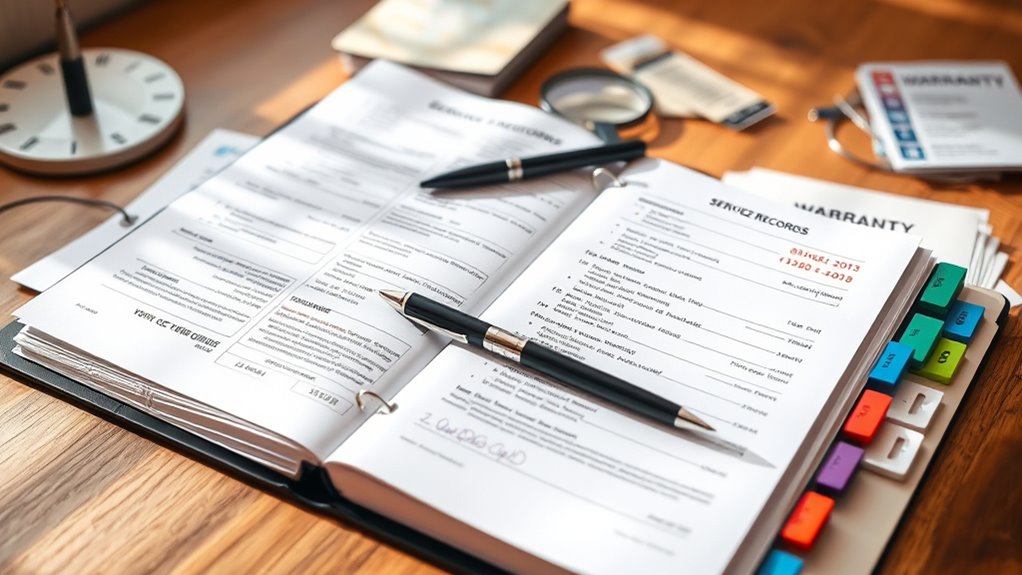

Key Elements to Include in Service and Warranty Logs

Creating detailed service and warranty logs requires you to include key elements that capture all relevant details of maintenance activities. These elements ensure clear, accurate records for future reference and warranty claims. Start with equipment identification, including a unique name or tag, serial number, model, manufacturer, and location. Document maintenance actions by recording date, type, specific tasks, technician or team involved, and any observations. Keep detailed parts and materials info, such as used components, quantities, serial or batch numbers, and approvals. Track equipment condition and performance metrics before and after maintenance, noting faults or operational changes. Finally, include personnel accountability details like technician contacts, supervisor approvals, certifications, and operator remarks. This comprehensive approach guarantees reliable, traceable records. Maintaining accurate logs also facilitates warranty validation and simplifies audits by providing comprehensive documentation.

Best Practices for Maintaining Record Integrity

Accurate and reliable service and warranty records depend on effective practices that uphold data integrity throughout their lifecycle. To achieve this, follow the ALCOA principles: ensure records are attributable, legible, contemporaneous, original, and accurate. Implement role-based access controls and multi-factor authentication to restrict unauthorized edits. Regularly audit user permissions and access logs to detect suspicious activity. Use data validation techniques, such as range checks and cross-field validations, to catch errors early. Encrypt records during transmission and storage with strong standards like AES-256, and protect encryption keys diligently. Maintain frequent backups and detailed audit trails to support data recovery and traceability. Consistent review of logs and automated integrity checks help prevent corruption and unauthorized changes.

| Practice | Benefit |

|---|---|

| ALCOA adherence | Ensures record integrity and authenticity |

| Access controls and audits | Prevents unauthorized modifications |

| Data validation, encryption, backups | Maintains accuracy, security, and recoverability |

Frequently Asked Questions

How Often Should Maintenance Records Be Reviewed and Updated?

You should review maintenance records at least monthly to monitor completion rates and guarantee timely inspections. For critical assets, consider weekly or bi-weekly reviews to prevent failures. Update records immediately after each maintenance task, including all relevant details like date, parts, and technician. Regularly audit logs quarterly to verify accuracy. Keeping records current helps you stay compliant with regulations, track performance, and identify recurring issues, ultimately improving your maintenance process.

What Are Common Mistakes to Avoid in Service Documentation?

You should avoid common mistakes like missing details, which disrupts care and legal protection. Don’t rely on illegible handwriting or unclear abbreviations, as they cause errors. Always update records promptly to maintain credibility. Steer clear of subjective comments or copying notes without review. Make certain all entries are accurate, signed, and free from tampering. By avoiding these pitfalls, you ensure your documentation remains reliable, professional, and compliant with standards.

How Can Digital Records Be Secured Against Unauthorized Access?

You can secure digital records against unauthorized access by employing strong encryption algorithms like AES-256 to protect data at rest and during transfer. Use role-based access control, multi-factor authentication, and regularly review permissions to limit access to authorized users only. Maintain detailed audit logs, store hardware securely, and implement strict operational policies. Regularly update security protocols and conduct audits to identify and fix vulnerabilities, ensuring your records stay protected from unauthorized access.

What Training Is Recommended for Staff on Record-Keeping Procedures?

Imagine your maintenance records as a well-organized library—every book, or record, needs proper labeling and care. You should train staff on record-keeping procedures through courses on maintenance documentation, digital tools, and regulatory compliance. Hands-on modules and online courses help staff learn to document repairs, inspections, and schedules accurately. This ensures consistency, reduces errors, and keeps your records audit-ready—making sure your maintenance library stays in perfect order.

How Do Record-Keeping Practices Vary Across Different Industries?

You’ll find that record-keeping practices differ across industries based on legal and regulatory demands. For example, healthcare requires secure, long-term storage of patient privacy records under HIPAA. Financial sectors focus on detailed transaction logs for audits, while manufacturing emphasizes traceability and safety documentation. You should adapt your practices to meet these industry-specific standards, ensuring compliance, secure storage, and easy retrieval for audits or legal needs.

Conclusion

By diligently maintaining detailed service records, you guarantee your equipment’s story remains both elegant and reliable. Thoughtful documentation not only preserves its value but also gently guides future care with clarity and confidence. When you approach this task with care and consistency, you subtly craft a legacy of trust and efficiency, allowing your machinery’s performance to flourish gracefully over time. In doing so, you uphold a tradition of excellence that speaks softly yet profoundly.