Ford Transit brake service involves understanding how the pads, rotors, and wear indicators work together. Your brake pads create friction against the rotors to stop the vehicle, while rotors can wear or warp over time. Wear indicators help you spot when pads are thin or components need replacement. Maintaining these parts guarantees safety and performance. Keep going to discover more about how these elements work and how to stay on top of brake maintenance.

Key Takeaways

- Ford Transit uses hydraulic disc and drum brakes with distinct components for front and rear braking systems.

- Brake pads create friction against rotors to slow the vehicle, with various materials affecting wear and performance.

- Rotor wear indicators and surface conditions signal the need for maintenance and help prevent damage.

- Proper brake pad replacement involves tools, supporting calipers, and ensuring correct assembly and fluid levels.

- Wear sensors and signs like noises or vibrations alert to brake system issues, emphasizing regular inspection and correct maintenance.

Understanding Ford Transit Brake System Components

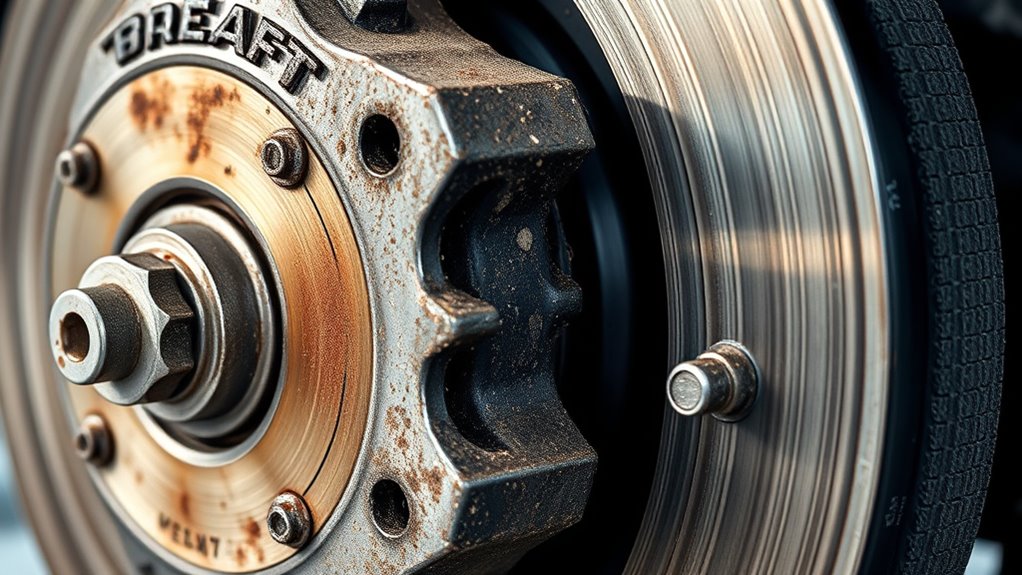

To understand the Ford Transit brake system, it’s important to know its main components and how they work together. The system uses hydraulic pressure to control all four wheels, with separate circuits for front disc brakes and rear drum brakes, ensuring safety through redundancy. The master cylinder pressurizes brake fluid, which travels through lines to calipers and wheel cylinders. When activated, pistons inside the calipers press brake pads against rotors, creating friction to slow the vehicle. Front brakes feature rotors, calipers, and pads, while rear brakes use drums and shoes. Additionally, a handbrake mechanism acts on the rear brakes via mechanical linkages, serving as a parking brake and safety backup. Maintaining fluid integrity and component condition is crucial for effective braking performance. Proper brake wear indicators help monitor component health and prevent failure, especially since they can alert you to issues before any significant braking performance decline occurs. Regular inspections of brake components are essential to ensure safety and optimal operation. Incorporating routine checks of wear indicator signals can help identify issues early, avoiding costly repairs and ensuring reliable braking.

The Role of Brake Pads in Safe Stopping

Your brake pads are essential for stopping safely because they create the friction needed to slow down or halt your vehicle. The material of the pads affects their durability and how well they perform under different conditions. Choosing the right pads guarantees consistent braking power and helps prevent costly damage.

Friction and Stopping Power

Have you ever wondered how brake pads actually help your vehicle stop quickly and safely? It all comes down to friction—when you press the brake pedal, the pads press against the rotor, converting kinetic energy into heat and slowing you down. The strength of this friction determines your stopping power. Higher friction means shorter stopping distances and less effort needed. The coefficient of friction (typically 0.3–0.5) measures how well the pad grips the rotor. Effective heat dissipation prevents fade, maintaining consistent friction. To deepen your understanding: Brake pads generate friction through contact with rotors and this friction is influenced by factors like pad material and surface texture. Friction converts kinetic energy into heat. Higher friction equals more effective braking. Heat management keeps friction consistent. Proper pad wear ensures reliable stopping power. This balance is essential for safe, reliable braking performance, especially when considering the WWE Raw’s financial impact on the entertainment industry, which illustrates the importance of maintaining peak performance and reliability in high-stakes environments. Additionally, understanding friction coefficient helps in selecting the right brake pads for specific driving conditions. Recognizing the importance of heat dissipation can greatly improve overall brake performance and longevity. Furthermore, advances in sound healing science have shown that proper heat management can also improve comfort and reduce stress during braking.

Pad Material and Durability

The materials used in brake pads directly influence their durability and performance, playing a key role in safe stopping. Semi-metallic pads, containing steel or iron, resist high temperatures and last longer but cause more rotor wear. Ceramic pads offer quieter operation and less dust, maintaining consistent friction, though they may wear faster under heavy use. Organic pads are softer, quieter, and gentle on rotors but tend to deteriorate quickly and produce more dust. Semi-metallic pads excel in high-temperature conditions, providing better stopping power but increasing rotor abrasion. Ceramic pads balance wear and performance, extending rotor life while ensuring smooth, quiet braking. Your choice impacts how long your brake components last and how reliably your Transit stops, especially under heavy loads. Understanding these differences helps in selecting the right brake pad material for your driving needs and maintenance preferences. Additionally, choosing biodiversity-friendly materials and practices can contribute to more sustainable automotive maintenance. Incorporating proper maintenance practices can further enhance brake performance and longevity, especially considering advances in AI-driven diagnostic tools that monitor brake wear and predict replacements before failure. Moreover, selecting eco-conscious materials can reduce environmental impact and support sustainable automotive care.

Features and Maintenance of Brake Rotors

Understanding rotor wear patterns helps you spot issues early, like grooves or uneven surfaces. Excessive heat can cause warping, leading to vibration and reduced braking performance. Paying attention to surface finishes guarantees your rotors stay smooth and effective for safe stopping. Regular inspection and maintenance can prevent deterioration caused by overheating, ensuring optimal brake function and safety. Additionally, monitoring worn brake pads can help identify early signs of rotor damage before more costly repairs are needed. Proper brake system maintenance is essential to extend rotor lifespan and maintain overall vehicle safety.

Rotor Wear Patterns

Rotor wear patterns reveal important clues about the health of your brake system, and recognizing these signs can help prevent more serious issues. Look for grooves, scoring, or uneven surface textures, which indicate progressive wear or potential damage. A glazed or shiny surface suggests overheating, reducing rotor effectiveness. Rust patches or discoloration signal corrosion and compromised integrity. Uneven wear often results from caliper misalignment or malfunction, causing inconsistent pad pressure. Tapered patterns may come from improper pad installation, while scoring can stem from worn pads or debris. Regularly measure rotor thickness; rotors thinner than 17 mm are unsafe. Incorporating visual inspections of wear patterns can also be beneficial for overall vehicle maintenance. Recognizing these wear indicators early allows for timely repairs, which can save money and improve safety. Staying attentive to these patterns and addressing them early keeps your brakes responsive, smooth, and safe, preventing costly repairs and ensuring peak stopping power. Additionally, monitoring for corrosion signs can help extend the lifespan of your rotors and maintain optimal braking performance.

Heat and Warping

Recognizing rotor wear patterns is only part of maintaining your brake system; understanding how heat affects rotors is equally important. Excessive heat from aggressive braking or repeated stops creates hot spots, causing uneven metal expansion and distortion. Driving downhill with continuous braking or hard braking at high speeds increases rotor heat, risking warping and uneven pad deposits. Poorly torqued lug nuts or low-quality rotors further heighten deformation risks under heat stress. Metal castings release internal stresses when overheated, and rapid cooling from water or puddles can induce thermal shock, worsening warping. To prevent this, avoid aggressive braking, use engine braking on descents, ensure proper lug nut torque, and select high-quality rotors. Regular inspections help catch early signs of overheating before serious warping occurs. Additionally, thermal expansion can be mitigated by allowing brakes to cool gradually after heavy use, reducing the risk of warping.

Surface Finishes

Surface finishes on Ford Transit brake rotors vary to enhance performance and durability. Most have smooth or plain disc surfaces for standard use, while drilled and slotted rotors feature holes and grooves that improve heat dissipation and debris removal. Zinc plating, in silver or black, protects against rust and corrosion, with silver coatings wearing off during initial bedding. Vented rotors, with internal vanes, help keep temperatures down and maintain surface integrity.

- Drilled holes evacuate gases and water quickly.

- Slots clean debris and deposits from pads.

- Smooth surfaces ensure quiet, consistent braking.

- Zinc and silver coatings defend against rust.

- Surface treatments influence bedding-in and wear.

Recognizing Wear Indicators and Their Significance

Understanding wear indicators is essential for maintaining your Ford Transit’s braking system, as they serve as early warning signals when your brake pads are nearing their minimum thickness. These sensors, either electrical or mechanical, activate alerts on the dashboard when pads become thin enough. Proper recognition prevents unsafe braking conditions. Be aware of common causes like wiring faults or sensor damage, which can trigger false warnings. Regularly inspect sensor wiring and connections to ensure reliability. Here’s a quick overview:

| Indicator Type | Signal Trigger | Common Issue |

|---|---|---|

| Electrical | Circuit opens or breaks | Wiring damage or wear |

| Mechanical | Metal tab contacts rotor or pad edge | Pad wear or sensor misalignment |

| Integrated | Sensor completion or circuit break | Sensor or wiring faults |

Stay attentive to these indicators to maintain safe braking performance.

Signs of Brake System Wear and When to Inspect

Paying attention to the signs of brake system wear helps you identify when it’s time for an inspection before problems worsen. Look for visual clues like brake pads thinner than 3mm, which indicate wear. Listen for squealing or high-pitched noises, signaling worn brake pad wear indicators contacting rotors. Grinding sounds mean pads are worn down completely, causing metal-to-metal contact. Feel for vibrations or pulsations through the brake pedal, often pointing to warped rotors or uneven wear. Watch for dashboard warning lights, such as brake pad sensors or brake warning alerts. Additionally, be alert to low brake fluid levels, soft or spongy pedal feel, and longer stopping distances. Regular inspections are essential, especially after heavy use or if any of these signs appear.

Proper Brake Pad Replacement Procedures

Replacing brake pads on your Ford Transit requires careful preparation and adherence to safety procedures. First, ensure you have the right tools, including a torque wrench, C-clamp or caliper compressor, and appropriate socket sizes like 13mm and 15mm. Secure the vehicle with a lift and remove the wheel. Wear gloves and safety glasses to protect against dust and debris. Disconnect the battery if needed, especially when working near ABS sensors. Remove the caliper slide bolts without putting strain on the brake line, then support the caliper to avoid damage. Detach old pads from the caliper bracket, clean slide pins, and compress pistons evenly. Install new pads, tighten bolts to specified torque, and double-check all components before reassembling. Pump the brake pedal to ensure proper contact and check fluid levels.

Ensuring Rotor Longevity and Safety Standards

Proper brake pad replacement is just one step in maintaining your Ford Transit’s braking system; ensuring rotor longevity and safety standards is equally important. To do this, avoid excessive heat buildup by not riding the brakes downhill and perform regular inspections of rotor thickness and surface condition. Use high-quality brake pads compatible with your vehicle to minimize abrasive wear. Properly torque rotor bolts (e.g., 20 ft-lbs plus 90 degrees) to prevent distortion. Always clean new rotors before installation to remove shipping grease and debris. Additionally, address any signs of vibration or noise promptly, as they can indicate rotor issues that compromise safety. Maintaining these practices helps extend rotor life, ensures consistent braking performance, and keeps you safe on the road.

Proper rotor care ensures safety, durability, and optimal braking performance for your Ford Transit.

- Avoid excessive heat buildup from aggressive braking

- Use quality brake components for durability

- Properly torque rotor bolts during installation

- Regularly inspect rotor thickness and surface condition

- Address noise and vibration issues immediately

Ford Transit-Specific Brake System Considerations

Understanding the Ford Transit’s brake system architecture is essential for effective maintenance and safe operation. It features dual-circuit, diagonally split hydraulic disc brakes, providing redundancy. Front brakes use ventilated discs ranging from 288 mm to 320 mm, depending on load and model year, while rear brakes typically have solid discs about 280 mm. The system includes vacuum servo assistance, ABS, Electronic Brake Distribution (EBD), and electronic stability controls like ESC and EBA. Brake wear is monitored by onboard sensors that trigger warnings before reaching critical limits, with discard thresholds around 30 mm for discs. Larger rotors are used for higher payload models to enhance heat dissipation. Brake hardware and software are tuned for load conditions and towing, ensuring safety and consistent performance across various driving scenarios.

Tips for Maintaining Optimal Brake Performance

Maintaining superior brake performance requires regular inspections and attentive care to identify wear or damage before it impacts safety. Start by visually checking your brake system every 10,000 miles or as recommended. Inspect brake pads for thickness, replacing them if below 3mm, and examine rotors for scoring or warping. Keep an eye on brake fluid level and quality, addressing contamination or low levels promptly. If equipped, monitor indicator wear sensors for alerts signaling pad replacement needs. To keep brakes in top shape, regularly:

Regular brake inspections every 10,000 miles help prevent wear and ensure safety.

- Clean components with non-chlorinated brake cleaner

- Clear debris from caliper slides with wire brushes

- Apply high-temperature brake lubricant to contact points

- Remove shipping grease from new rotors before installation

- Check hydraulic hoses and connections for leaks or cracks

Frequently Asked Questions

How Often Should I Replace My Ford Transit Brake Pads?

You should replace your Ford Transit brake pads roughly every 30,000 to 70,000 miles, depending on your driving habits and conditions. Regular inspections help catch wear early, especially if you notice squealing, longer stopping distances, or changes in pedal feel. Keep an eye on visual wear indicators and have your brakes checked during routine maintenance. Replacing pads before they’re too thin ensures safe stopping and prevents rotor damage.

What Are the Signs of Worn Brake Rotors?

You’ll notice worn brake rotors through unusual squealing, squeaking, or grinding noises when braking. Look for grooves, scratches, or visible surface damage, and feel for vibrations or a wobbling sensation during stops. If your brake pedal feels spongy or presses farther down, or if your vehicle pulls to one side, these are signs rotors may be warped or worn out. Regular inspections help catch these issues early.

Can Brake Wear Indicators Fail Prematurely?

Yes, brake wear indicators can fail prematurely. You might notice false warnings or the indicator circuit breaking due to wiring damage, corrosion, or manufacturing defects. Sometimes, the sensors or wiring harnesses wear out faster than expected, especially under harsh conditions. If you see warning lights despite new pads, it’s essential to examine the wiring, connectors, and sensor integrity to prevent unnecessary replacements and ensure your braking system functions correctly.

Are Aftermarket Brake Parts Suitable for Ford Transit?

Yes, aftermarket brake parts are suitable for your Ford Transit, but you need to verify compatibility. You should match the specific model year and brake system size to find the right pads and rotors. Choosing reputable brands like Duralast Gold or BrakeBest helps ensure quality and durability. Proper installation, lubrication, and following maintenance guidelines will keep your braking system functioning safely and effectively, saving you money without sacrificing performance.

How Does Driving Style Affect Brake Pad Lifespan?

Your driving style directly impacts brake pad lifespan. If you accelerate quickly and brake hard often, your pads wear out faster due to increased heat and friction. Conversely, smooth, gradual braking and anticipating traffic help extend pad life. Avoiding aggressive driving, maintaining safe distances, and driving on flatter terrain reduce wear, saving you money on replacements. Remember, your driving habits play a vital role in how long your brake pads last.

Conclusion

Your Ford Transit’s brakes are its heartbeat on the road—without them, safety falters. Regular inspections, timely replacements, and understanding each component’s role keep your vehicle confident and dependable. Think of your brake system as a symphony; when all parts work in harmony, your stopping power remains flawless. Stay vigilant, care for your brakes, and enjoy the smooth, secure ride you deserve. After all, isn’t safety the true destination?