To insulate your transit van effectively, choose materials like spray foam for high R-values and airtight sealing, or rigid foam boards for durability. For noise reduction, consider dense mats or insulation layers that absorb sound vibrations. Keep moisture control in mind—proper ventilation and moisture-resistant materials prevent mold. Safety is key, so select fire-rated options. If you want practical tips and product ideas, stick around to discover how to create a quieter, more comfortable van environment.

Key Takeaways

- Use high R-value materials like spray foam or rigid foam board for effective thermal insulation in vans.

- Incorporate soundproofing layers such as dense mats or fiber insulations to reduce noise transmission.

- Proper installation involves precise cutting, fitting, and sealing to prevent gaps that compromise thermal and acoustic performance.

- Combining thermal and acoustic materials enhances overall comfort, especially in noise-prone areas like floors and driver cabins.

- Consider moisture-resistant and fire-safe options, and ensure proper ventilation to prevent mold and maintain safety standards.

Types of Insulation Materials Suitable for Transit Vans

Choosing the right insulation materials for your transit van is essential to guarantee warmth, soundproofing, and durability. Rigid foam board insulation, like polyisocyanurate or extruded polystyrene, offers high compressive strength and good thermal performance, making it ideal for floors and walls that endure heavy wear. It’s easy to cut and resistant to moisture, preventing mold and rot. Spray foam insulation creates an airtight seal, filling gaps and improving thermal efficiency, while adding structural rigidity. Thinsulate, a lightweight synthetic fiber, excels at reducing noise and handling variable climates. Natural wool insulation offers breathability, moisture regulation, and soundproofing, all without chemicals. Reflective foil insulations are thin and lightweight, perfect for boosting overall thermal performance in limited spaces. Select based on your specific needs and space constraints. Spray foam offers the highest R-value and permanent insulation, making it a popular choice for maximizing thermal efficiency in transit vans. Additionally, advancements in insulation technology continue to improve energy efficiency and ease of installation for various materials. Incorporating thermal performance considerations can significantly enhance comfort and energy savings in your van conversion.

Understanding R-Values and Thermal Performance

Understanding R-values is essential for evaluating how well insulation materials resist heat transfer, which directly affects your van’s interior comfort. R-value measures thermal resistance, with higher values indicating better insulation per inch. It accounts for conduction, convection, and radiation collectively, influencing your heating and cooling needs. Materials like spray foam (R-6.5) offer higher R-values than fiberglass (R-3.5), meaning less energy is required to maintain comfortable temperatures. Doubling insulation thickness roughly doubles the R-value, and trapped air within cavities adds extra resistance. Moisture and vapor barriers impact performance; improper moisture control can degrade insulation. Selecting the appropriate insulation type based on your climate and usage is crucial for optimal results. Choosing the right R-value helps reduce energy costs and enhances comfort, especially in variable climates. Insulation installation techniques also play a crucial role in achieving optimal thermal performance.

Acoustic Insulation Solutions for a Quieter Ride

Choosing the right soundproofing materials can make a big difference in how quiet your van feels. Proper installation practices guarantee these materials work effectively and last longer. By focusing on both material selection and correct application, you’ll create a more comfortable, noise-free ride.

Soundproofing Materials Selection

Selecting the right soundproofing materials for your transit van is essential to achieving a quieter ride and a more comfortable interior. Your choice depends on factors like weight, noise type, durability, and budget. For vibration damping, dense butyl mats like Dynamat are effective but add weight. Foam and fiber insulations, such as Thinsulate or jute-based products, absorb airborne noise and reduce resonance. Spray-on coatings like LizardSkin offer seamless coverage for targeted damping without extra bulk. Consider water resistance for durability and conformability to fit irregular shapes. Budget-friendly options include recycled fibers, though they may be less effective at blocking impact noise. Combining materials tailored to your noise sources and interior needs maximizes soundproofing efficiency. Incorporating a variety of soundproofing techniques can enhance overall noise reduction and improve comfort during your rides. Additionally, understanding material properties helps in selecting the most suitable insulation for specific applications. Using acoustic insulation solutions that are lightweight and easy to install can further optimize your soundproofing efforts.

Installation Best Practices

Proper installation of acoustic insulation is crucial to maximizing its noise-reducing benefits in your transit van. Start by removing all interior panels, trims, carpets, and flooring to expose clean, bare metal surfaces. Thoroughly clean these surfaces with degreasers and microfiber cloths to ensure good adhesion. Check for holes, rust, or damage, and repair them to prevent sound leaks. Make certain the surfaces are completely dry before applying insulation. Measure and cut sound-deadening mats precisely to fit key areas like doors, walls, and floors. Peel off the adhesive backing and smooth out mats, pressing with a roller for full contact. Limit coverage to about 25% of each panel to optimize performance and cost. Focus on noise-prone areas such as the driver’s cabin and floor for the best results. Additionally, staying informed about AI vulnerabilities helps ensure the safety and effectiveness of your insulation project. Being aware of soundproofing technology can guide you in selecting the most effective materials for your needs.

Factors to Consider When Installing Insulation

When installing insulation, you need to guarantee the material fits well and is compatible with your van’s surfaces to prevent gaps or damage. It’s also essential to choose moisture-resistant options to avoid mold and maintain performance over time. Don’t forget to verify that your insulation meets fire safety standards for a safe, compliant build. Proper installation techniques are crucial to ensure maximum effectiveness and safety of your insulation.

Material Compatibility and Fit

Ensuring insulation materials work well with your van’s surfaces is essential for a durable and effective installation. You need materials that adhere properly to metal frames, walls, and ceilings without degrading over time. For example, closed-cell foam and Thinsulate repel moisture and resist compression, making them highly compatible with metal surfaces. Be cautious with materials like fiberglass, which may shed particles and struggle to stick without vapor barriers. Thermal breaks like Low-E EZ-Cool provide added compatibility by resisting compression when mounting cabinetry. Pre-cut kits, such as 3M Thinsulate for Ford Transit, ensure precise fit and good contact with surfaces. Proper compatibility guarantees insulation stays in place and performs effectively, especially in irregular cavities and behind built-in structures. Additionally, selecting insulation with moisture resistance ensures longevity and prevents mold growth in the damp environment of a transit van. Choosing materials with good thermal insulation properties helps maintain desired temperatures and enhances overall comfort inside your van. Considering material compatibility can also simplify installation and reduce the need for adjustments or additional adhesives.

Moisture and Mold Control

Effective moisture and mold control in your van hinges on managing the humidity levels and airflow inside the space. Proper ventilation is essential to reduce interior moisture from activities like breathing, cooking, or showering. Increasing air recirculation helps keep humidity in check; for example, recirculating air every 27 minutes with two occupants in a Ford Transit. Ventilation prevents trapped moisture from condensing on cold surfaces, reducing mold risks. Using dry heat sources alongside ventilation keeps surfaces above dew point temperatures. Choose insulation that complements moisture management—natural fibers like wool buffer humidity, while synthetic options like Thinsulate dry quickly. Avoid relying solely on vapor barriers, as they can trap moisture. Instead, promote consistent airflow and consider moisture-buffering materials to prevent mold growth and maintain a healthy environment. Incorporating knowledge of aircraft safety and proper ventilation techniques further enhances moisture control efforts. Proper air circulation is key to preventing moisture buildup and ensuring a healthy, mold-free interior environment. Additionally, selecting insulation materials with moisture-buffering properties can further help manage indoor humidity levels effectively.

Fire Safety Compliance

Installing insulation in transit vans requires careful attention to fire safety standards to protect passengers and meet regulatory requirements. You must select materials that comply with standards like FMVSS 302, ASTM D-3675, and adhere to guidelines from the FTA. Proper installation is vital—avoid gaps, voids, or compression that can fuel fires. Use fire-resistant adhesives and sealants to maintain safety integrity. Ensure compatibility between insulation, vapor barriers, and wiring to prevent hidden fire hazards. Choose materials that retain fire-resistant properties over time, resisting heat, vibration, and moisture. Keep thorough documentation of certifications and testing results. Regular inspections and maintenance are essential for ongoing compliance. In addition, choosing insulation materials that are certified fire-resistant and tested for flammability helps ensure long-term safety and regulatory adherence. Properly installed insulation with certified fire-resistant materials minimizes potential fire risks and maintains compliance standards over the lifespan of the vehicle. Additionally, understanding how attention in creative practice can improve problem-solving skills might inspire innovative approaches to selecting and installing insulation materials effectively. Being aware of asset division laws can also be useful when considering any legal aspects related to vehicle modifications or ownership transfers.

Environmental and Health Aspects of Insulation Choices

Choosing the right insulation for your transit van means considering both its environmental impact and how it affects your health. Some foam boards, like XPS and EPS, use chemical blowing agents that emit high greenhouse gases, harming the environment. Natural materials such as wool, recycled denim, and cellulose have a much lower footprint and are renewable or recycled. These options help reduce emissions and support sustainability. Health-wise, fiberglass and mineral wool can release fibers and VOCs, posing respiratory risks. Natural wool resists mold, regulates humidity, and improves air quality without harmful chemicals. Selecting insulation without volatile compounds and with recycled content minimizes health risks and environmental harm, making your van safer and more eco-friendly for long-term living. Additionally, choosing insulation materials that are free from volatile compounds can further enhance indoor air quality and safety, aligning with sustainable building practices that prioritize eco-conscious choices.

Popular Insulation Products and Kits for Vans

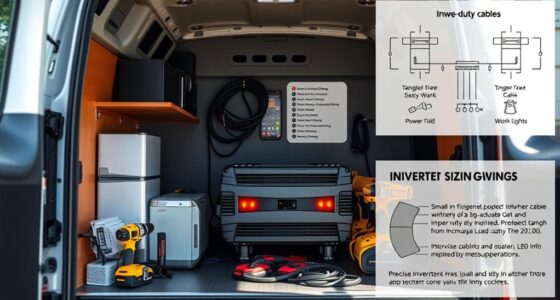

When selecting insulation for your van, convenience and fit can make a big difference in the installation process and overall performance. Pre-cut kits, like the “23+ Ford Transit 148 WB High Cube Ext,” are designed specifically for your van model, reducing errors and saving time. These kits often include 30mm D-Mat insulation for thermal and sound control, plus damping materials such as Boom Mat to eliminate vibrations. Spray foam offers high thermal resistance and excellent sealing but needs professional application to avoid gaps. Thinsulate is favored for its ease of install, moisture resistance, and acoustic benefits. Reflective barriers like Prodex reflect radiant heat, especially when combined with other layers. Traditional batt insulation is less ideal due to settling and moisture issues, making newer materials more popular.

Combining Thermal and Acoustic Insulation for Optimal Comfort

Combining thermal and acoustic insulation in your transit van creates a more comfortable and quiet interior by addressing two key factors simultaneously. Using dual-function materials like 3M Thinsulate SM600L simplifies installation while providing both thermal regulation and sound dampening. Thermal insulation keeps the interior temperature stable, making your van warm in winter and cool in summer, boosting comfort. Acoustic insulation blocks road and ambient noise, creating a quieter, more relaxing environment. Materials with vibration-damping properties, such as Thinsulate, reduce metal vibrations and decrease noise without adding weight. Additionally, combining these insulations lowers moisture buildup by managing condensation, preventing mold and mildew. Thinsulate’s hydrophobic fibers resist moisture, mold, and mildew, enhancing overall durability. Proper layering—soundproofing first, followed by thermal and acoustic foam—ensures ideal performance, resulting in a more pleasant driving and living space.

Tips for Maintaining and Upgrading Your Van’s Insulation

Maintaining and upgrading your van’s insulation guarantees it continues to perform effectively over time. Regular inspections help catch issues like moisture buildup, leaks, or damage early, ensuring insulation stays intact. Check for condensation, wet spots, or gaps, and replace compromised materials promptly. Use a vapor barrier carefully, only when you can ensure airtight sealing to prevent mold and rot. Keep humidity levels in check with a dehumidifier, and manage ventilation by cleaning roof vents and ensuring proper airflow. To upgrade, consider adding extra layers, sealing seams tightly, and replacing outdated materials with modern, moisture-resistant options.

- Inspect insulation regularly for damage or moisture

- Seal gaps and cracks to prevent drafts

- Use reflective panels to reduce heat transfer

- Double insulation layers for better R-value

- Replace old materials with advanced, moisture-resistant options

Frequently Asked Questions

How Do I Choose the Best Insulation for Different Climates?

To choose the best insulation for different climates, first consider your area’s temperature and humidity. In cold climates, opt for high R-value materials like wool or layered Thinsulate. For warmer, humid areas, use moisture-resistant options like foam boards or Thinsulate. If noise reduction is a priority, wool or Thinsulate work well. Always match insulation properties to your climate, installation ease, and environmental preferences for ideal performance.

Can Insulation Improve My Van’s Fuel Efficiency?

Yes, insulation can improve your van’s fuel efficiency by reducing the energy needed to maintain internal temperatures. Better insulation minimizes heat transfer, lowering the workload on cooling or heating systems and decreasing fuel consumption. Choosing high R-value materials like PIR boards keeps the van temperature stable without adding excessive weight. Proper insulation also reduces the need for frequent door openings, helping you save fuel and cut emissions.

What Are the Fire Safety Considerations for Van Insulation?

You can guarantee fire safety by choosing insulation with proper fire ratings, like mineral wool, which is inherently non-combustible. Avoid foam insulations unless they have verified fire retardants and adhere to regulations like NFPA 285. Proper installation is key—secure panels, avoid voids, and add fire-retardant coatings if needed. Also, install fire-rated cladding and maintain safe electrical practices to prevent ignition risks.

Is It Necessary to Upgrade Insulation Over Time?

Yes, you should upgrade your van’s insulation over time. Environmental exposure, wear and tear, and moisture can diminish its effectiveness, leading to condensation, mold, or thermal bridging issues. Regular inspections help you spot problems early, like persistent moisture or cold spots. Upgrading insulation with durable, moisture-resistant materials ensures your van stays comfortable, energy-efficient, and protected from damage, saving you money and hassle in the long run.

How Does Insulation Affect Ventilation and Moisture Control?

Insulation acts like a sponge, absorbing and holding moisture inside your van walls. It affects ventilation and moisture control by trapping humidity, which can lead to mold if not managed properly. You need to balance insulation with adequate ventilation, like roof vents or screened windows, to allow moist air to escape. Proper airflow prevents condensation, keeps your van dry, and maintains a healthier environment while optimizing insulation benefits.

Conclusion

Think of your van as a ship sailing smoothly through unpredictable waters. With the right insulation, you’re steering toward calmer seas—warmth, quiet, and comfort as your steady compass. Proper insulation isn’t just about blocking the cold or noise; it’s about creating a sanctuary amid the chaos. When you choose wisely and maintain your setup, you’re guiding your vessel with confidence, ensuring every journey feels like returning home — safe, cozy, and in control.